Understanding Cement with Vicat Testing

- June 25th, 2024

- Category: Equipment Guides

Understanding Cement with Vicat Testing

The quality and performance of cement are crucial in construction projects. Vicat testing is a vital tool for assessing these properties, ensuring the cement meets the required standards. This blog post dives into the world of Vicat testing, explaining the different tests conducted and how they provide valuable insights into cement behavior.

Three Key Vicat Tests:

- Consistency Testing (ASTM C187): This test determines the amount of water needed to create a cement paste with "normal consistency." This consistency ensures optimal strength development in the final product. The Vicat apparatus with a plunger is used to measure penetration depth in cement mixtures with varying water content. The ideal consistency is achieved when the plunger penetrates 10 ± 1mm.

- Initial Setting Time (ASTM C191): This test defines the time it takes for cement paste to transition from a liquid to a plastic state. It essentially indicates the timeframe within which the cement mortar or concrete needs to be placed for optimal strength. The Vicat apparatus with a 1mm needle is used to measure penetration depth. The initial setting time is reached when the needle no longer penetrates the paste deeply.

- Final Setting Time (ASTM C191): This test signifies the time it takes for the cement paste to lose its plasticity completely and become solid enough to withstand pressure. It determines when concrete hardens sufficiently to hold its shape, allowing for formwork removal. Like the initial setting time test, the Vicat apparatus with a needle is used. The final setting time is reached when the needle makes an impression on the paste surface but doesn't leave a complete circular mark.

Factors Affecting Setting Times:

Several factors influence both initial and final setting times of cement, including but not limited to:

- Cement Type: Different cement types have varying inherent setting times.

- Fineness of Cement: Finer cement particles generally lead to faster setting times.

- Chemical Additives: Certain additives can accelerate or retard setting times.

- Sand Content: The presence of sand in mortar or concrete can affect setting times.

- Ambient Temperature: Colder temperatures usually result in slower setting times.

- Water Content: The amount of water used in the cement mix significantly impacts setting times.

Performing Vicat Tests:

There are two primary methods for Vicat testing:

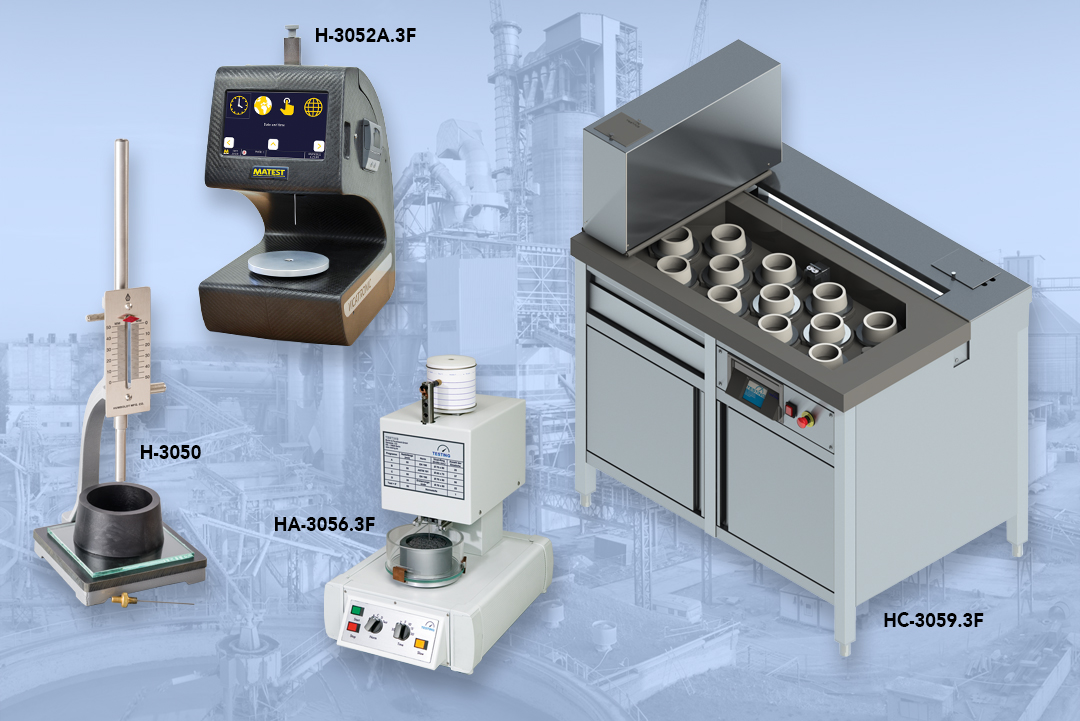

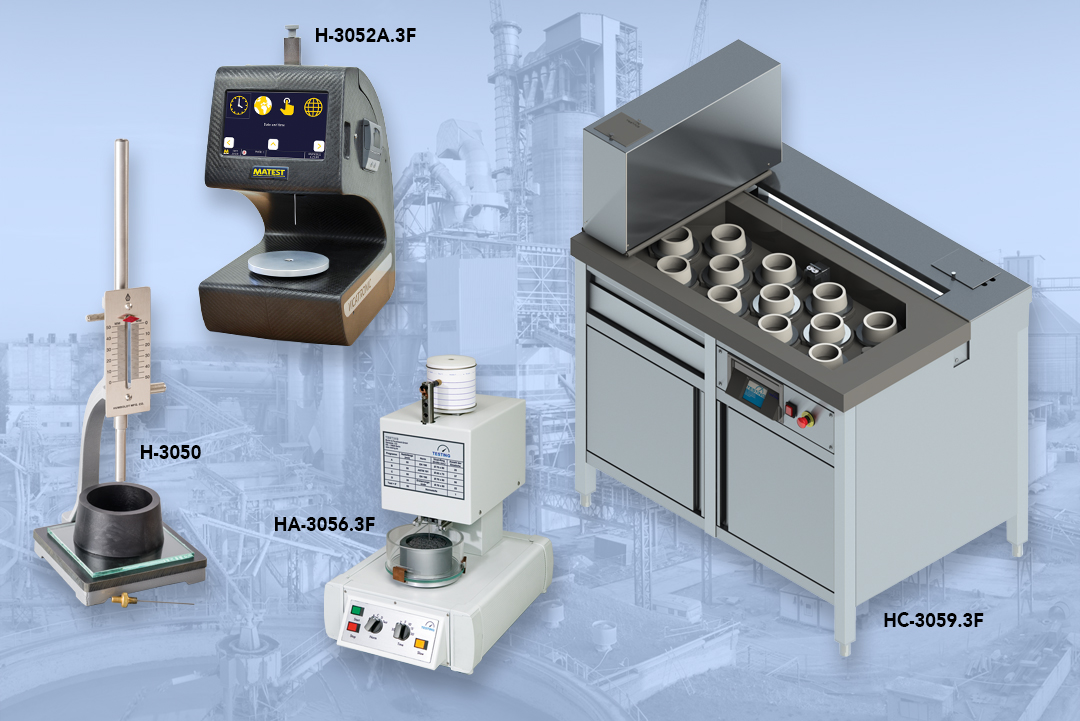

- Method A: Standard Vicat Apparatus (ASTM C191): This manual method involves a Vicat apparatus with a plunger and needles. The cement paste is molded and placed in a moist environment for setting. The penetration depth of the needles is measured at regular intervals to determine initial and final setting times.

- Method B: Automatic Vicat Apparatus (ASTM C191): This method utilizes automated Vicat machines that perform the testing procedure and record data. These machines offer improved accuracy and repeatability compared to manual testing.

Vicat testing provides valuable insights into the setting behavior of cement, ensuring its suitability for various construction applications. By understanding the different tests, factors affecting setting times, and testing methods, construction professionals can make informed decisions about cement selection and usage.