H-2783A

Humboldt Concrete Air Meter

Features all-brass H-2785.DB super pump for reliability and faster operation.

H-2787

Concrete Air Meter

Features cast-in handles and high-quality clamps

H-2786.XX

Press-Ur-Meter Concrete Air Meter

Determine air content, specific gravity and free moisture test of aggregates.

H-2796A

Roll-A-Meter Air Indicator

This aluminum Roll-A-Meter is used to determine the air content of concrete mixes, containing lightweight aggregate

H-2795P

Volumetair Air Meter

Used for the rolling method of measuring entrained air in any concrete.

H-2756

Chace Concrete Air Indicator Kit

Complete kit for measuring air content of fresh concrete.

H-2755

Chace Concrete Air Indicator

For quick field checks for air content of fresh concrete in about three minutes.

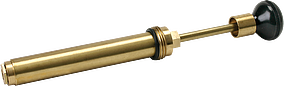

H-2785.DB

Super Pump for Air Meters

The Super Pump's all brass construction resists acids in cement.

H-2782

Air Entrainment Meter, 8L

The H-2782 8 Liter air meter features push-buttons for simple test performance.

H-2781

Air Entrainment Meter, 5L

The H-2781 5 Liter air meter features push-buttons for simple test performance.

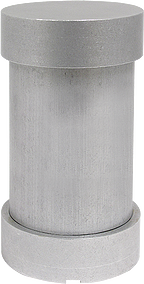

H-2788

Concrete Air Meter Calibrator (5%), Plastic

Calibrator checks the accuracy of any pressure-type concrete air meter.

H-2789

Concrete Air Meter Calibrator (5%), Brass

Brass, Concrete Air Meter 5% Calibrator

H-2793

Concrete Air Meter Calibrator (5%), Aluminum

Concrete air Meter Calibrator with aluminum construction

Air Meters and Indicators

Controlling the air content through air entertainment is essential in many types of concrete. With an air-entraining meter, small, uniform air bubbles are deliberately created within a concrete mixture. These bubbles are between 0.1mm and 1mm in diameter and protect concrete exposed to freezing and thawing from damages caused by freezing water. By serving as air voids in the hardened concrete, the bubbles relieve pressure without causing damage and thus extend a mix’s lifetime.

The Importance of Air Content Testing

Air meters and indicators are used to determine the air content of fresh concrete at the point of placement. Because mixing, transporting, pumping and handling a mix can take out valuable air bubbles, the final air content of concrete must be tested at the right time and place. Therefore, mix evaluations throughout the settling process is essential. A complete air content reading guarantees that the concrete will be durable under freeze/thaw conditions when insitu.

Even concrete that is not exposed to freeze/thaw conditions is often tested for air content. While non-air-entrained mixes contain air contents between 1% and 2%, concrete with more than 3% entrapped air is prone to surface defects and delamination. Because of this, air content testing can locate issues before they occur and is valuable for a complete mix analysis.

There are multiple air content testing methods, all of which provide valuable information about a concrete sample and its workability. While many variations, there are three main practices of air content testing:

1. The Pressure Method for Air Content utilizes pressure air meters to provide quick, reliable results. Using an upper chamber of air and a lower chamber of concrete, air is pressurized and released into the lower chamber. The bubbles formed by the concrete compressing under increased pressure are measured and used to determine the air content of the concrete. This method is best for lightweight or normal-weight concrete mixes.

2. The Volumetric Method for Air Content instead uses volumetric air meters or roll-a-meters. This practice takes significantly more time and effort but can be used for all concrete mixes. In this method, a specimen is filled with both water and isopropyl alcohol until the air voids are effectively washed out of the mix. The difference in fluid levels before and after the procedure is recorded as the air content of the concrete mix.

3. The Gravimetric Method involves a wide range of equipment including unit weight measures, tamping rods and strike-off plates. Using the specimen weight and actual batch weights, calculations are executed to determine concrete air content and many other properties of the mix. Because slight variations can cause relatively large errors, this method is best for trial mix designs.

Since there are multiple ways to test air content of fresh concrete, you have to be careful not to only go by the initial results. Assessment outcomes can vary especially based on conditions. Specifically on large quantities of concrete, it can be important to do further investigation with both field and lab tests.

Humboldt provides a wide selection of Air Meters and Indicators to choose from. If you have questions or need help selecting equipment, please call us at 1.800.544.7220 or use our Ask Humboldt form.