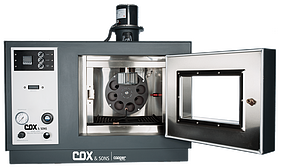

H-30069.XX

Rolling Thin Film Oven, Digital

Used to measure the effect of heat and air on a moving film of semi-solid asphaltic material.

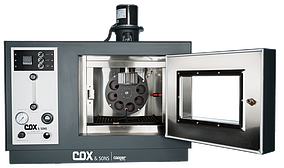

H-30068.XX

Rolling Thin Film Oven, Analog

Used to measure the effect of heat and air on a moving film of semi-solid asphaltic material.

RTFO

The Rolling Thin-Film Oven (RTFO) is a vital piece of equipment used to simulate the short-term aging of asphalt binder. This aging process occurs during the production and paving of asphalt mixtures. The invention of the RTFO by James Cox & Sons led to the present day AASHTO, ASTM and EN standards for Effect of Heat and Air on a Moving Film of Asphalt Test utilizing the Rolling Thin-Film Oven. This test method is intended to measure the effect of heat and air on a moving film of semi-solid asphaltic materials as outlined in ASTM D2872 and AASHTO T 240. Since asphalt binder in HMA undergoes significant aging during the manufacturing and placement processes, a method to simulate the aging is important in investigating and predicting HMA pavement behavior and distresses. Specifically, the Superpave binder specification calls for short-term, aged asphalt binder to be tested at high temperatures to determine fatigue and rut resistance.

The basic test procedure using the Rolling Thin-Film Oven takes unaged asphalt binder samples placed in cylindrical glass bottles and places these bottles into a rotating carriage within the oven. The carriage rotates within the oven while the 325°F (163°C) temperature ages the samples for 85 minutes. The effects of this treatment are determined from measurements of the selected properties, such as a change in mass, of the asphalt before and after the test. This test method indicates approximate change in properties of asphalt during conventional hot-mixing at about 302°F (150°C) as indicated by viscosity and other rheological measurements. It yields a residue which approximates the asphalt condition as incorporated in the pavement. If the mixing temperature differs appreciably from the 302°F (150°C) level, more or less effect on properties will occur. This test method also can be used to determine mass change, which is a measure of asphalt volatility.

RTFO Test Applications

The RTFO test can be used in the study of the effects of aging on various asphalt binder modifiers, additives, or new formulations. This aids in developing improved asphalt binders that offer enhanced durability and performance.

Regulatory agencies typically require asphalt binders to meet certain aging criteria. The test using the RTFO can be used to ensure compliance with these specifications before the asphalt binders are used in road construction projects.

The data obtained from the test using the RTFO, combined with other aging tests like the Pressure Aging Vessel (PAV) test, helps in predicting the long-term performance of asphalt pavements. This information guides pavement design and maintenance strategies.

The RTFO is also used to assess the suitability of recycled materials, such as reclaimed asphalt pavement or recycled asphalt shingles in asphalt mixtures. Understanding how these materials age and affect the overall mix is critical for sustainable pavement practices.

The test using the RTFO assists in understanding the chemical and physical changes that occur to asphalt binders due to aging, including changes in viscosity, hardness, and ductility, which impact the performance of asphalt pavements.

Humboldt Rolling Thin-Film Ovens

Rolling Thin Film Ovens available in Digital or Analog models.

Through the use of a programmable, temperature controller and a 4-digit, digital display system, along with a solid-state heater and 200-watt heating element, the oven accurately maintains the specified test temperature of ±1°F at 325°F (±0.5°C at163°C). The specially designed and unique heating solution means that the heat is evenly spread during the test, ensuring results are correct and repeatable. Cox & Sons RTFO is the reference in the world.

- Invented, designed and manufactured in California

- Super accurate P.I.D. controller

- Low thermal mass RTD

- Over temperature safety cut-out

- Double walled temperature cabinet

- Unique temperature control suppression

The oven features: double-wall construction; door with double-pane viewing window; symmetrical top and bottom vents; air plenum, and squirrel-cage-type 1725 rpm fan. The RFTO is available in a standard model with a glass flow meter or with a digital flow meter. Both models are identical other than the meter.

RTFO Ovens Include:

- 200 to 14,000 ml/min flow meter

- Moisture meter

- 0 to 100 psi air pressure gauge with regulator

- Rotating (15rpm) test rack.

- 8 Glass sample containers