HM-5170A.3F

CBR/LBR and Marshall Automatic Load Frame

Designed for doing CBR soil testing and Marshall testing in the same lab.in the same lab.

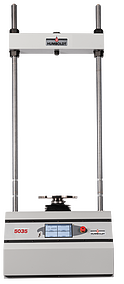

HM-5035.3F

Load Frame, Master Loader Plus, Elite Series, 15000 lbf (68KN)

Designed to handle multiple applications requiring up to 15000 lbf (68KN)

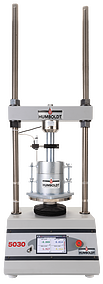

HM-5030.3F

Load Frame, Master Loader, Elite Series, CBR/LBR

A multi-purpose loading system, that provides CBR/LBR capabilities

HM-5150A.3F

CBR (California Bearing Ratio) Automatic Load Frame

Complete load frame solution for CBR and LBR testing

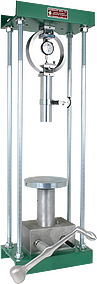

H-4156

CBR Mechanical Loading Press

The unit provides rapid travel of the platen for positioning of the sample.

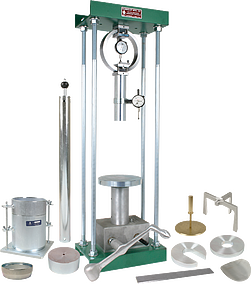

H-4152

CBR Mechanical Test Set

The CBR Testing Set includes all the items needed for testing with the H-4156.

HM-5030U

Load Frame UPGRADE for, Elite Series Master Loader

UPGRADE your HM-3000.3F Master Loader to the New HM-5030.3F

HM-5170A.3F

Marshall and CBR/LBR Automatic Load Frame

Designed for doing Marshall asphalt testing and CBR soil testing in the same lab.

HM-2850.3F

Load Frame, Multi-Speed for CBR

Multi-speed load frame without built-in data acquisition.

CBR Load Frames

CBR (California Bearing Ratio) test was developed by The California State highway department. CBR is widely used to to evaluate the potential strength of subgrade, subbase, and base course materials, including recycled materials for use in the design of road and airfield pavements. The CBR test is outlined in ASTM D1883 and AASHTO T193. The test involves a simple penetration test using a load frame and a standard, compacted CBR test mold of the material to be tested. The results of the test are then compared and evaluated to known standards already established for the material being tested.

ASTM D1883 covers the determination of the CBR or California Bearing Ratio of pavement subgrade, subbase, and base course materials from laboratory compacted specimens. The test method is primarily intended for, but not limited to, evaluating the strength of materials having maximum particle size less than 3/4 in. (19 mm).

LBR or lime-rock bearing ratio is a variation of the CBR test. Developed primarily in Florida, it is used on materials with a high lime content.

Humboldt offers several CBR testing load frame solutions based on your overall testing needs and budget, from the advanced HM-5030.3F load frame with computer interface using our NEXT software to a simple, hand-operated H-4156 load frame suitable for lab or field use.

Humboldt's Elite Series Load Frames provide the materials testing lab with a choice of three, highly-versatile and precision-built loading systems covering a range of testing applications. The HM-5030 is the workhorse of the group, capable of handling any testing need up to 50kN or 11,000 lbf.

These machines provide four (4) integral and independent data acquisition channels, which can be utilized in stand-alone configurations or accessed through a LAN-networked computer using Humboldt's Next Software. Elite series load frames are built with durable, high-quality components and feature the use of a stepper motor, precision gears and gear box to ensure smooth and reliable operation, as well as precise results.

In stand-alone mode, these load frames provide a 7" (178mm) touch-screen controller. These new waterproof, touch screens provide colorful, at-a-glance monitoring of testing functions without the use of a computer. Operators can see all the data in several formats at the machine while the test is running. Data can then be viewed simultaneously or downloaded later to a computer in the lab, in the next room or at a different location, while also providing report generation capabilities from within Humboldt's NEXT software or our enhanced test-specific modules.

Also available is our basic multi-speed machine, the HM-2850. This load frame is designed for those who want a simple, high-quality, multi-purpose load frame without built-in data acquisition capabilities.